Hello, I use sweepme to call owis ps-10 operator to operate motorDMT65-DM6-HSM#1603. I set the parameters to make it run. The program has no errors. The motor makes a faint vibration sound, but does not rotate. The ps-10 green light flashes, indicating that the reference position is invalid. How can I operate it? Thank you for your help.

Hi,

this is difficult to debug if there is no error message.

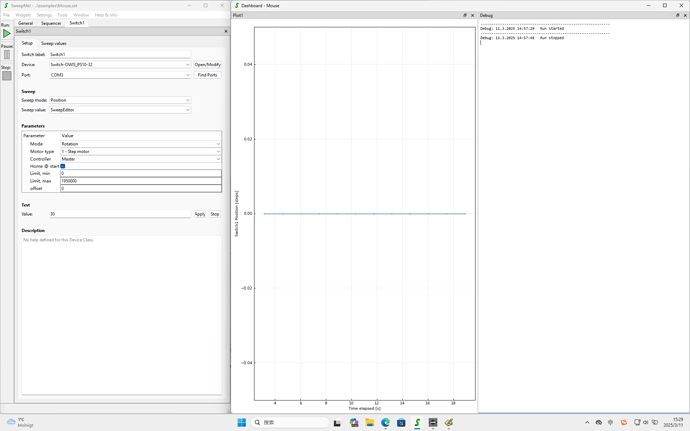

Your configuration of the driver in the Switch module looks good.

As a first step, I would test whether the motor movement is possible with the software provided by OWIS. Can you test whether the motor can do a homing and move to different positions.

Further, you can use the Port manager of SweepMe! via menu “Tools” → “Port manager” and check the debug flag for your COM port. This way you can log the communication to the Debug widget and we can see to which extent the driver works and when it stops.

It could be that some professional support from us is needed to debug the problem in a joint video meeting. Let us know if this could be an option for you by writing to contact@sweep-me.net

Good luck and best

Axel

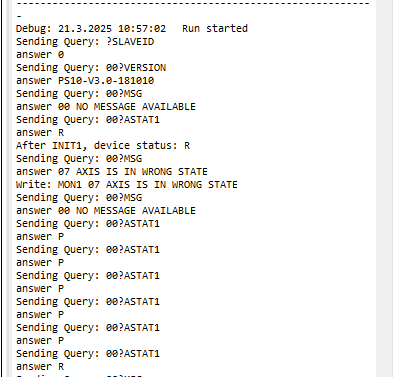

Yes, i can control it by owis sofatware i can set position and let it move to there. I use Sweepme to print this

![]()

If the OWIS software can control it, then there seems just to miss a certain configuration in the SweepMe! driver to run it with your model.

Can you also send the debug log when you use the debug check for your COM port in the Port manager of SweepMe!. Then, I could see which commands are written and which messages are received from the driver.

I guess you already know how to modify drivers. You can always create a custom version of SweepMe! driver where you can make your own modifications. This is deschribed here:

https://wiki.sweep-me.net/wiki/Version_manager#Create_custom_versions

This way you can check which commands are send, add/modify/remove commands and test the driver until it works for you.

Best, Axel

Hi,

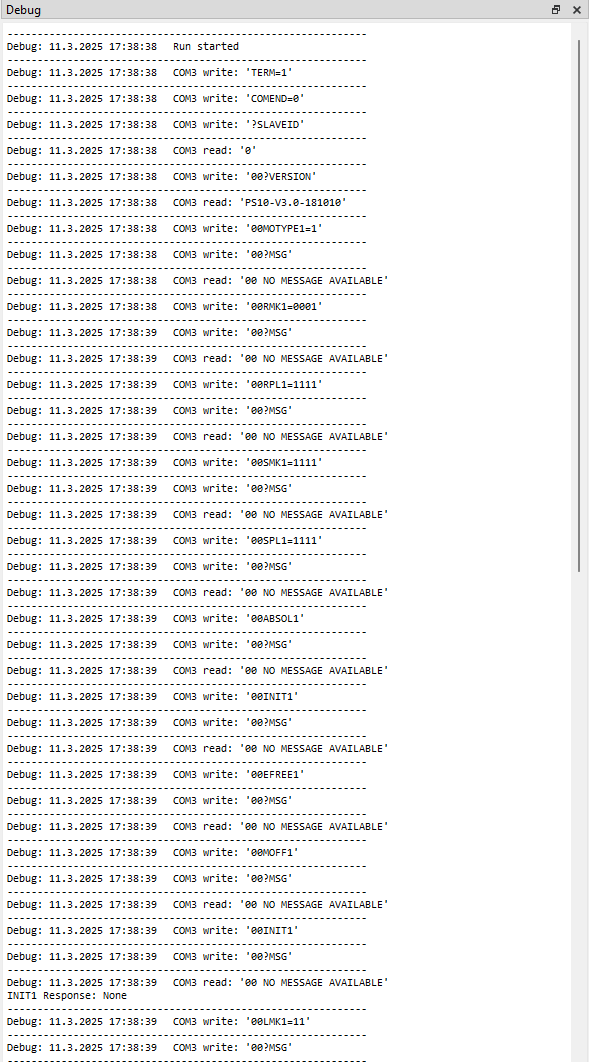

thanks for sending the debug output of the port manager.

The driver is written in a way that after each command a check is performed whether a error message is generated. If so it is written to the Debug.

As you already indicated in your previous message, the driver has the line

“Write: MON1 07 AXIS IS IN WRONG STATE” after sending the commands “MON1”. This probably means that the axis is not correctly configured during “initialize” and the “configure” phase of the driver.

The driver was originally written and tested for linear stages but should also work for rotational stages as the basic command protocol is the same. It could be that some other configurations must be set.

In general, the driver needs some overhaul. For example, the driver does not stop the measurement if an error message is detected.

Here, you can find the manual from OWIS:

https://www.owis.eu/uploads/tx_aimeos/files/3/3/336cbf3e_PS_10_User_Manual_pdf.pdf

The way to fix the driver would be to create a custom version of the driver in the version manager of SweepMe! and then start adding or modifying the driver until it works. The fact that the communication already works flawlessly with the PS-10 controller is definitely helpful to quickly test other command or the commands with other parameters.

In the forum, we can just give some first hints how to do in on your own. If you need our help with debugging the driver during a joint video meeting you can write to contact@sweep-me.net and we are happy to assist you in a project.

Of course, you could also test our Driver Writer AI, by uploading the manual and the current driver and ask how it must be modified to work with a rotation stage.

https://chatgpt.com/g/g-679c9a16da048191be552b2246512077-sweepme-driver-writer

Best, Axel

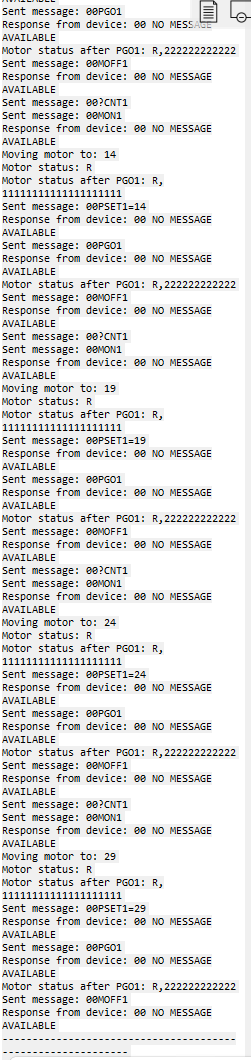

I modified the code and output the status of the command. I found that they all showed ready and sent the command normally, but why didn’t the motor turn?

ps-10.py (11.8 KB)

You could check whether the OWIS software has a feature to see which commands are sent or whether there is any configuration to the one sent in the SweepMe! driver.

Additionally, you can check whether the parameters of the commands are correct. Maybe try to uncomment some configurations like Polarity or limit switches in the “initialize” phase to see whether that helps. Try to reduce the driver to the minimum needed. Some of the commands might be permanently stored on the motor controller. So, you could use the software from OWIS to setup the rotation stage once and only use the essential commands in the driver like MOFF, MON, INIT, ASTAT, PSET, and PGO.

Further, check whether there are commands in the manual that need to be added that are not sent yet at all.

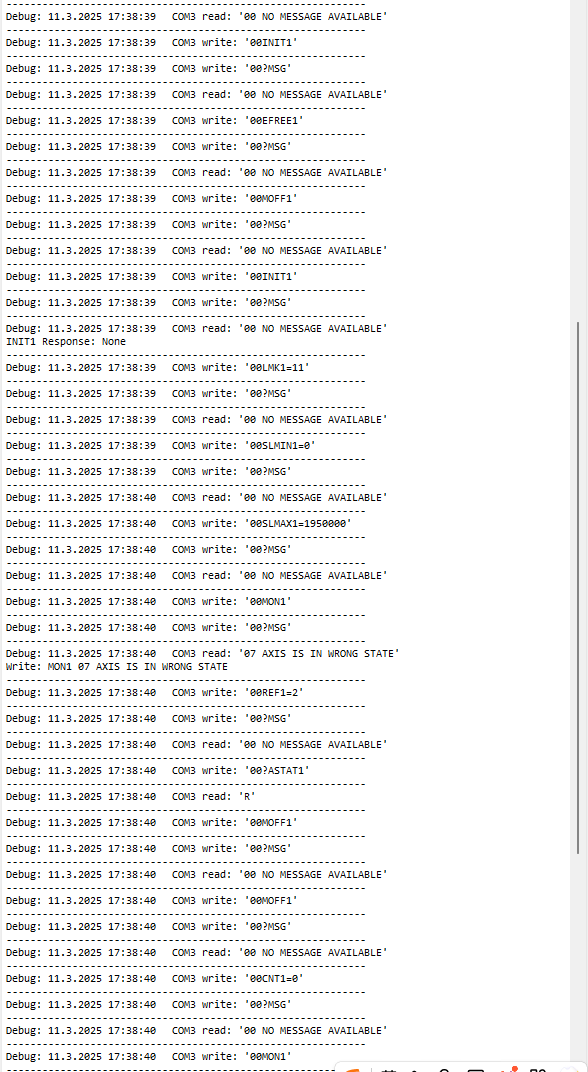

Hello, thanks for your suggestion. I used the method pre-configured in owissoft. I configured the parameters in owissoft so that both LED lights are on. Then save the parameters to EEPROM (I use direct command to read RMK1=0001 RPL1=1111 SMK1=0000 SPL1=1111), then enter sweepme to operate. I do not use any write instructions after INIT1, and the status after INIT1 also shows R. But once I use MON1 to turn on the motor, it reports an error Sending Query: 00?MSG

answer 07 AXIS IS IN WRONG STATE

Write: MON1 07 AXIS IS IN WRONG STATE This causes my motor to be unable to start moving. I found that the most important step to make the green light flashing and turn it into a solid green light when using owissoft for configuration is to let the motor return to the reference position in the axis parameters interface. There is no such step in the sweepme code. After the sweepme code reports an error, I open sweepme and there is an error of about 0.004 degrees. Is this the reason why I can’t start the motor? If so, what should I do? At present, my practice is to save the parameters to EEPROM after configuring them in owissoft. Then use Sweepme to INIT1

ps-10-321.py (11.4 KB)

Hi Deng,

from your screenshot it looks like that already after “INIT1” the answer comes with “07 AXIS IS IN WRONG STATE”.

The axis state is retrieved via ASTAT1 and results to letter “R”. Here, you can check the documentation what “R” means and whether this state is also present before and after INIT1. Then, you could check whether all parameters are correctly set before INIT1 by using commands that retrieve the parameters from the controllers.

If this does not help, you can check the OWIS documentation and check whether there is further help to each error message.

Hope you can finally solve it. Looks like it is just one thing to change and it will work, but figuring this out could still take a bit time.

Best, Axel

You can further check how the Homing operation works. At the moment, this is done during ‘initialize’ when the user has selected the corresponding check box in the UI of the Switch module.

Here you could test what happens if you omit homing and you could check whether the homing commands are correctly used in your case.

Best, Axel

This is the executable code (initialized using owissoft and control input using sweepme)

Note: After the code is changed, the input rotation unit is degrees, the source code is steps, 1steps represents 5000 steps

Real_Motor.py (10.8 KB)

Hi Deng,

congratulation to get it working and thanks a lot for sharing your working example.

Can you comment on what finally made it working?

How did you resolve the problem that the axis was in the wrong axis state?

Thanks and best

Axel

Two things need to be care:

- unit, 1 degree means 5000 steps, if use original code, should input steps as unit

- initialization by owisoft, Engineer of owisoft said it need more setup(besides RMK1 RPL1 SMK1 SPL1), just input INIT1 in sweepme to read the parameter in EEPROM.

- IF meeting"Axis in the wrong state", don’t input"MON1" to open the motor, The axis is already switched on with INIT. If you then send MON1, you want to switch on an axis that is already active. This triggers the error. => Only use INIT.

Here are the modifications you made to the code:

1. __init__ Method

- Original Code: Lacked the line

self.steps_to_deg = 5000. - Modified Code: Added

self.steps_to_deg = 5000to define the conversion factor between steps and degrees.

2. get_GUIparameter Method

- Original Code: Used

self.limitmax = int(float(parameter["Limit, max"])). - Modified Code: Changed to

self.limitmax = int(float(parameter["Limit, max"])*self.steps_to_deg)to incorporate the steps-to-degrees conversion.

3. initialize Method

- Original Code: Several lines were commented out:

# self.write("MOTYPE1=%s" % self.motortype) # self.write("RMK1=0001") # self.write("RPL1=1111") # self.write("SMK1=1111") # self.write("SPL1=1111") # self.write("ABSOL1")- Modified Code: Uncommented these lines to make them executable.

- Original Code: Lacked

time.sleep(0.1)afterself.write("INIT1").- Modified Code: Added

time.sleep(0.1)to wait for the device to process the command.

- Modified Code: Added

- Original Code: Did not print the device status after querying.

- Modified Code: Added

print("After INIT1, device status:", status)to display the device status.

- Modified Code: Added

4. configure Method

- Original Code: Used

self.write("REF1=2"). - Modified Code: Changed to

self.write("REF1=4")to adjust the reference position setting.

5. apply Method

- Original Code: Lacked

self.value = self.value*self.steps_to_deg. - Modified Code: Added this line to convert the value to steps.

6. reach Method

- Original Code: Used

time.clock().- Modified Code: Replaced with

time.time()sincetime.clock()is deprecated in Python 3.8.

- Modified Code: Replaced with

- Original Code: Did not print the status.

- Modified Code: Added

print("Sending Query: {full_msg}")andprint("answer",answer)to print the query command and the response.

- Modified Code: Added

7. query Method

- Original Code: Directly used

self.port.write(slave+"?"+query).- Modified Code: Changed to

full_msg = slave + "?" + queryandself.port.write(full_msg)to store the complete query command in a variable and print it.

- Modified Code: Changed to

8. write Method

- Original Code: Used

self.port.write(slave+msg).- Modified Code: Added

print("Write:", msg, answer)to print the message and the response.

- Modified Code: Added

9. measure Method

- Original Code: Did not print the command.

- Modified Code: Added

print("Sending Query: ?CNT1")to print the query command.

- Modified Code: Added

10. read_result Method

- Original Code: Did not print the result.

- Modified Code: Added

print("Current position:", self.current_position)to print the current position.

- Modified Code: Added

Thanks a lot for posting this. I think it is a good and recommended approach to do the basic setup of the linear stage with the manufacturer software, save the parameters permanently and only control the movemement with SweepMe!.

Good results!

Best, Axel